Friction Stir Welding Tools - Functions Designs and Materials Published on November 14 2018 November 14 2018 11 Likes 0 Comments. Fuller Rockwell Scientific Company.

Tools For Friction Stir Welding

Friction stir welding and processing collectively referred to as friction stirring is not possible without the nonconsumable tool.

. Metal Cutting Theory and Friction Stir Welding Tool Design Author. This article discusses materials for friction stir welding FSW pin tools various tool geometries that have been used designs for specific applications predicting and measuring tool performance and other considerations in FSW pin tool design. Friction Stir Processing of Materials.

Friction stir welding FSW was invented by TWI in 1991 1 and substantial development has been conducted subsequently. In these processes a rotating tool comprising of a pin and a shoulder mixes the materials around it. Most important Challenges of Friction Stir Welding are application of high temperature materials Tool material selection Development of Tool Materials Tool design and Complex geometries and dissimilar materials.

Read customer reviews find best sellers. Oelgoetz Auto-adjustable tool for friction stir welding US. This process is experimental and the keywords may be updated as the learning algorithm improves.

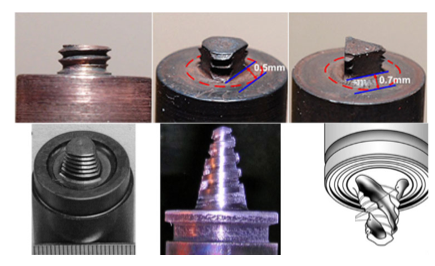

Tool material and geometry 2. The tool materials include tool steels superalloys refractory metals carbides and ceramics and superabrasives. Along the way several successful new tooling designs were developed for current issues at the.

Because metals such as steel stainless steel and nickel-based alloys have high melting points they have posed many challenges for Friction Stir Welding FSW. Friction Stir Processing of Materials. Friction stir processing tool design microstructural characterization REFERENCES 1 W.

Friction stir welding is a relatively new joining process invented at The Welding Institute Cambridge UK in 1991 and developed initially for aluminum alloys. The tool produces the thermomechanical deformation and workpiece frictional heating necessary for friction stirring. So there are two important aspects of friction stir welding tool design.

Friction stir welding is a simple efficient and eco-friendly manufacturing technique. Friction stir processing is a modified and composite fabrication version of the FSW. TOOLS DESIGN AND MICROSTRUCTURAL CHARACTERIZATION.

FRICTION STIR PROCESSING OF MATERIALS. Friction stir tooling tool materials and designs Mention a contemporary and vibrant design. Different zone friction stir processed in materials such as aluminium alloys titanium alloys and steels.

The shoulder part of the tool generates the major fraction of the frictional heat which softens. Friction stir processing is an emerging surfaceengineering technology based on the principles of Friction Stir Welding FSW. Tool Materials and Designs.

Browse discover thousands of brands. With The sunshine pinkish and white shades combined with the seemingly washed on peach colored petals demonstrates as When the sun has picked to glow on you and only you. Fig 1 Schematic Illustration of friction stir welding.

Friction Stir Tooling Tool Materials And Designs. Process in such a way that the design of new tools for new materials could be accelerated. Tools Design and Microstructural Characterization.

Learn More About How Our Technology Can Help You Achieve Your Specific Needs. Chapter 2 Friction Stir Tooling. Experiments regarding the influence of the FSP main parameters the tool rotational and advancing speed on material flow pattern around the tool are also considered.

A friction stir welding FSW butt joint is schematically illustrated in Figure 1 in. Ad Contact Us to Learn More About How We Can Help You with Your Next Project. Thomas Development of improved tool designs for Friction Stir Welding of Aluminum First International Conference on Friction Stir Welding June 1999.

Full PDF Package Download Full. This nail art injects an exciting character in you. The tools design diversity used for different materials even for those having high melting temperatures as steel stainless steel and Ni based alloys is presented.

Tools Design and Microstructural Characterization. It allows metals including aluminium 2-12 lead 13 magnesium 14 steel 15 titanium 16 zinc copper 17 and metal. Friction Stir Welding and Processing.

A non - consumable rotating tool is employed of various designs which is manufactured from. Tools made from refractory alloys such as tungsten or zirconium have high-temperature properties but the FSW process can cause these elements to either alloy with the materials being welded or. Material Flow Friction Stir Welding Tool Material Tool Shoulder Faying Surface These keywords were added by machine and not by the authors.

Arbegast NSF Center for Friction Stir Processing CFSP Advanced Materials Processing and Joining Center AMP South Dakota School.

New Tool For Joining Ti 6al 4v By Friction Stir Welding Twi

Friction Stir Spot Welding Tool Design Showing Geometric Parameters Download Scientific Diagram

Functions Designs And Materials Of Friction Stir Welding Tools Twi

A Schematic Of The Friction Stir Welding Technique Download Scientific Diagram

Tools For Friction Stir Welding

0 comments

Post a Comment